ACS Materials Letters, 2022, 4, 1967–1975

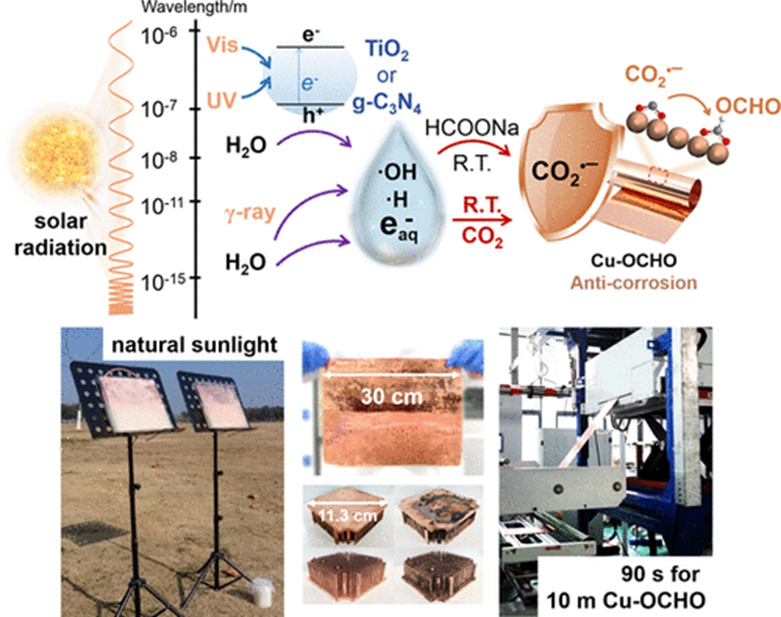

Abstract: Introducing the durable oxidation resistance of refined copper on a large scale while retaining valuable physical properties has great operational and economic benefits for everyday industry but remains a challenge. Here, we report a strategy for the preparation of antioxidant copper under ambient UV/visible or high-energy irradiation using surface-coordinated carbon dioxide anion radicals (CO2•–). It is shown that effective adsorption of CO2•– on copper leads to further formation of bidentate formate multilayers, which hardly degrades surface characteristics but is resistant to chemical attack from a range of highly corrosive solutions such as H2O2, NaCl, Na2S, and NaOH. Due to the universality of free radical production, the anticorrosion procedure requires no high temperature and pressure, as well as the specific container, enabling the processing of various sizes and shapes of copper materials. In addition, we demonstrated several practical advantages: the passivation of different shapes can be easily achieved under natural sunlight; using an industrial electron beam, 10 m oxidation-resistant copper foil can be made in only 90 s. The antioxidation method can use waste CO2 as CO2•– source, thus opening up a complementary opportunity for CO2 immobilization.

Link: https://pubs.acs.org/doi/full/10.1021/acsmaterialslett.2c00624

--校内链接--

--校外链接--

微信公众号